LIQUIDS TOLL MANUFACTURING

Chemical raw materials stored in the logistics area of the company are used as a basis.

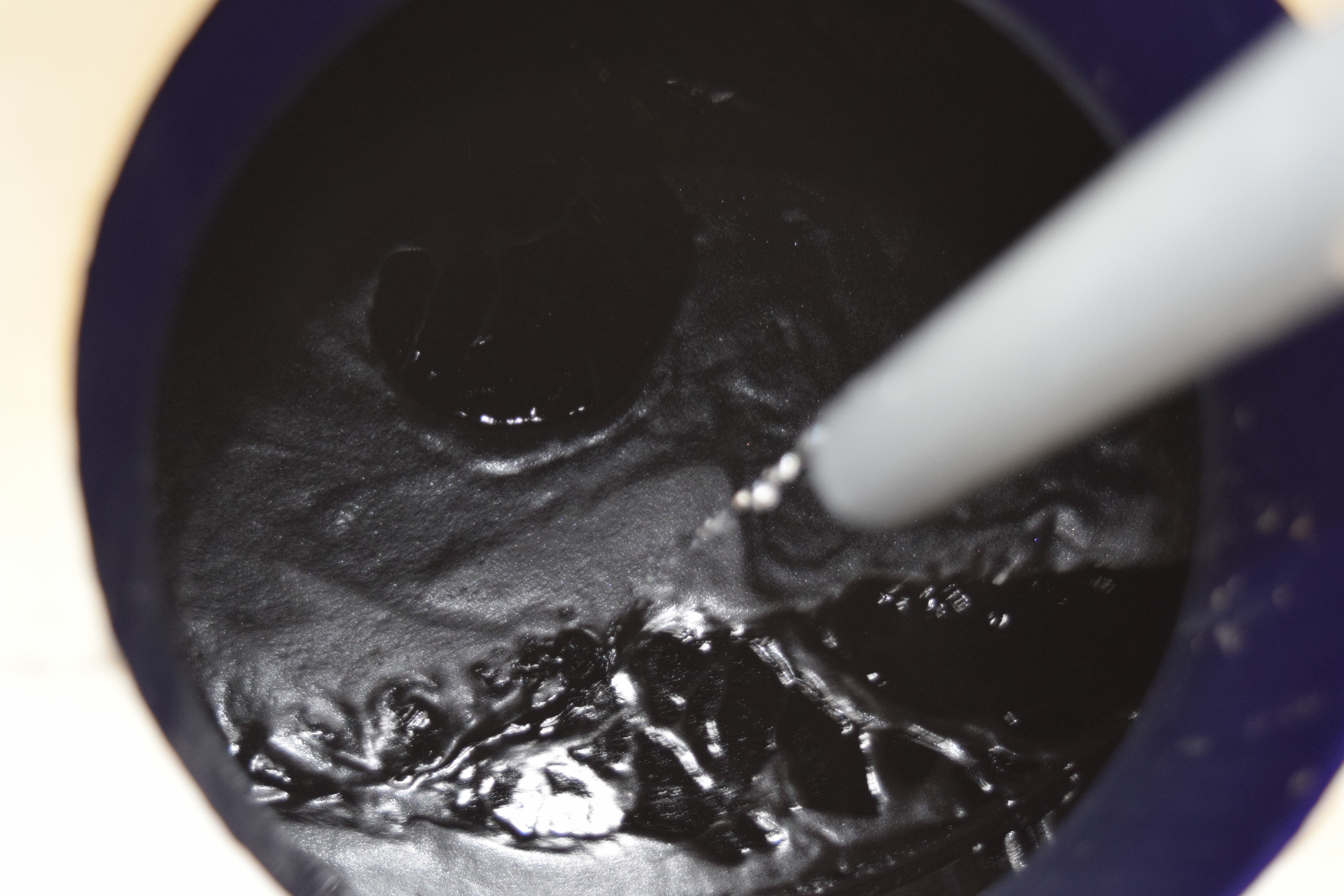

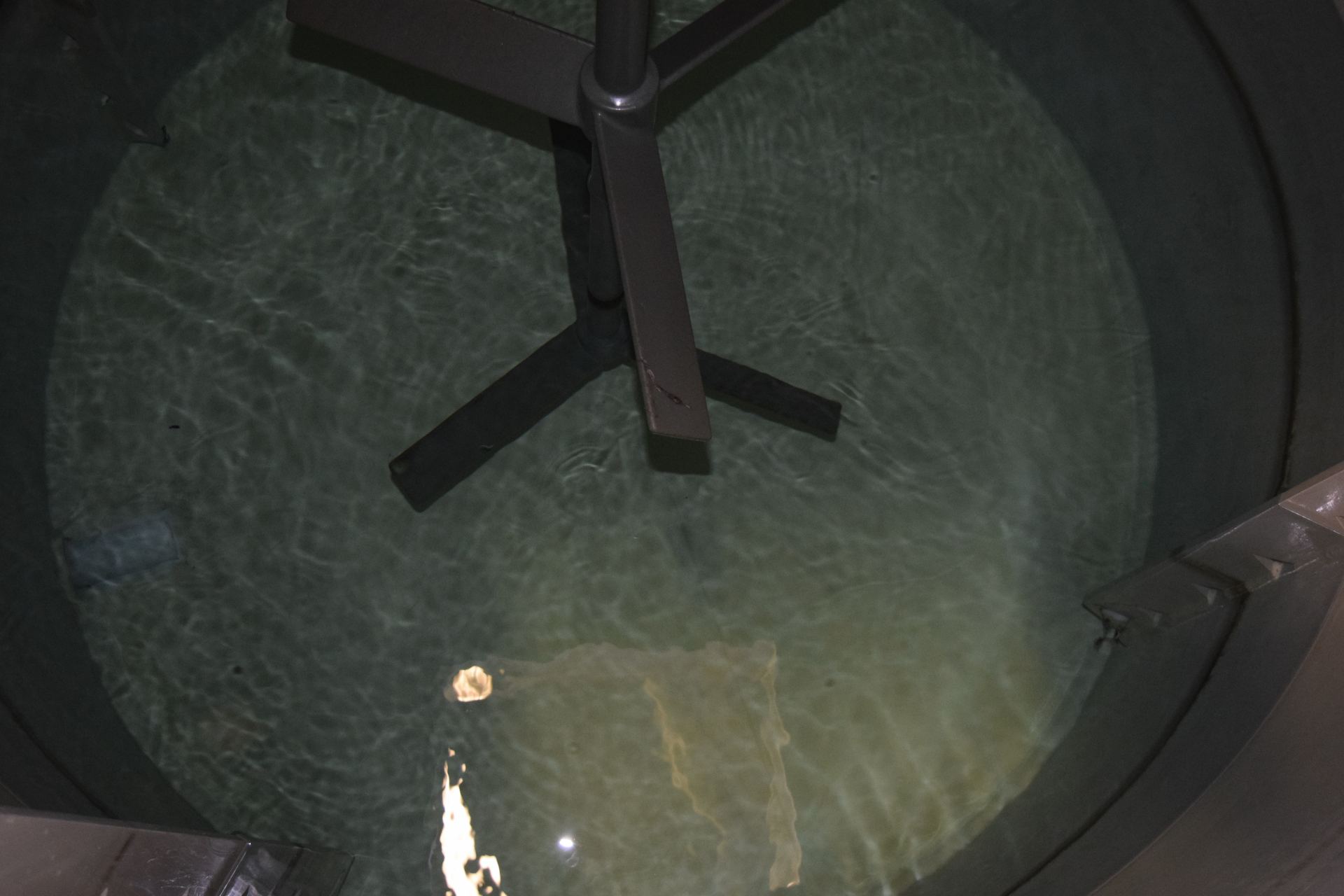

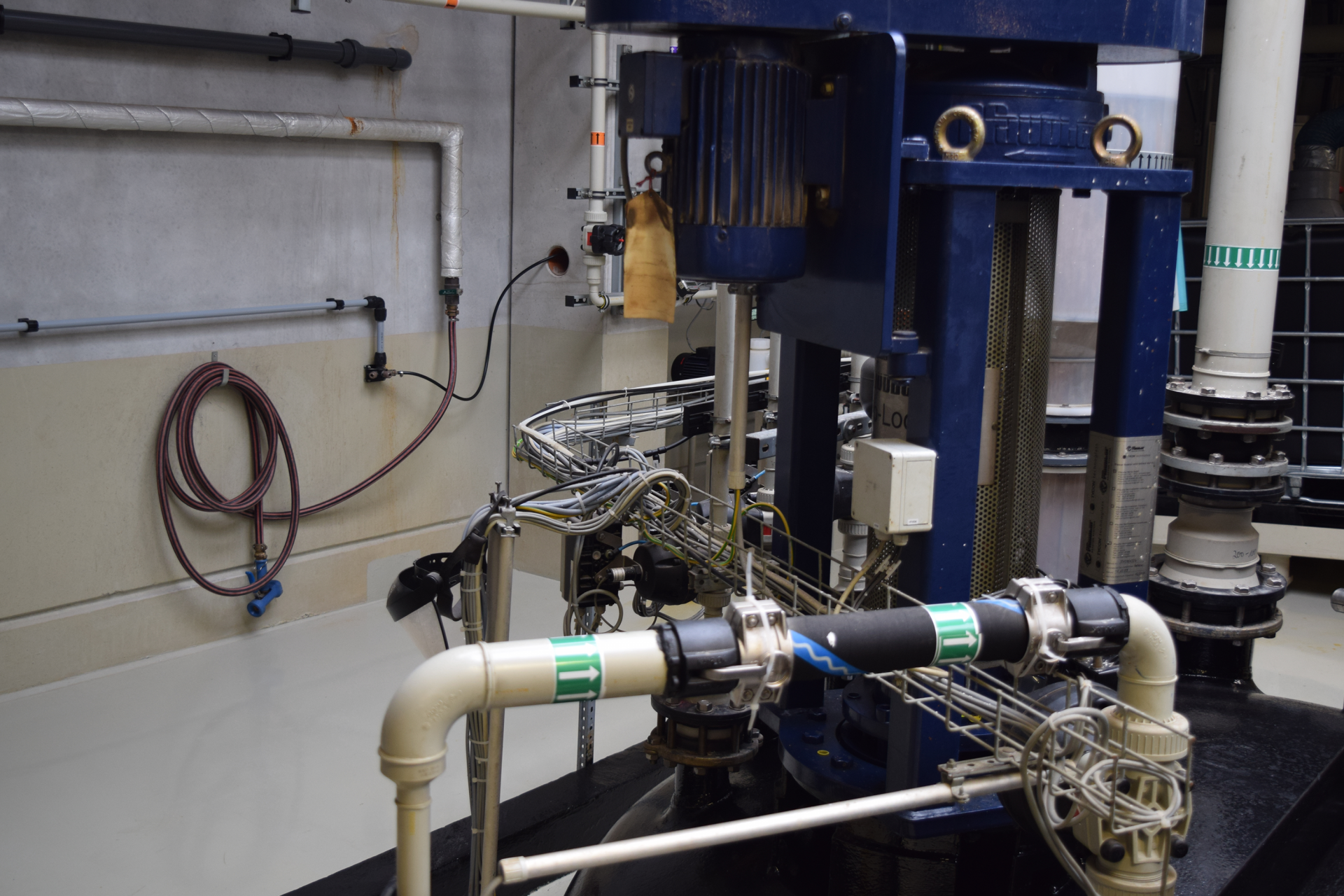

Our liquids production has stainless steel and plastic mixing vessels used for the batch production of liquid preparations. We offer batch mixtures with sizes in the order of 50 – 15,000 litres / batch

In order to offer the broadest range of services possible, our mixing containers are partially equipped with cooling and heating systems

MIXING POSSIBILITIES

- Various mixing containers with up to 8 m³ made of both plastic (PP/PVDF) and stainless steel

- Glass-enamelled reactor plants with up to 15 m³

- ECTFE-coated agitator vessels

- Pilot reactor for sample quantities of up to 100 l

- Process control acc. to SIL2

- Active cooling and heating resources

- Small-scale production in batch sizes of 100-1,000 kg

- Semi-automatic filling stations for various container sizes

REACTION CHEMISTRY

Gefahrstoffzentrum (GSZ) Kaiserslautern GmbH has enamelled and ECTFE-coated agitator vessels used to produce substances via chemical reactions in batch sizes of up to 15,000 litres / batch. We also have a glass-enamelled test agitator vessel that allows us to produce sample preparations for you from 30 litres / batch

ACTIVE COOLING/HEATING RESOURCES

- In order to offer the broadest range of services possible, our mixing containers are partially equipped with cooling and heating systems

PROFESSIONAL CONSULTING BY GEFAHRSTOFFZENTRUM (GSZ) KAISERSLAUTERN GMBH

We are happy to advise you about our possibilities for liquids production.

Please contact us directly.

FAQ

Waht mixing containers do you have and what are the batch sizes like ?

We have various mixing containers with up to 15 m³, plastic (PP/PVDF), stainless steel and glass enamelled.

The batch sizes for small quantities are 100 – 1,000 kg, the maximum batch size is 15m³.